8 Ways Oil & Gas Companies are Embracing Digital Transformation

According to a recent study by Accenture, 70% of Oil & Gas leaders view enterprise-wide digital transformation as a critical component to remaining competitive. Yet a separate report by McKinsey has found that 70% of Oil & Gas companies have failed to make it past the pilot phase of their digital transformation intiatives.

What's Hampering Progress?

Digital transformation is the reimagining and restructuring of an organization's operations, strategies, and culture through the integration of technology.

It holds immense potential to create value in the energy sector by enabling organizations to lower costs, enhance output, and streamline operations.

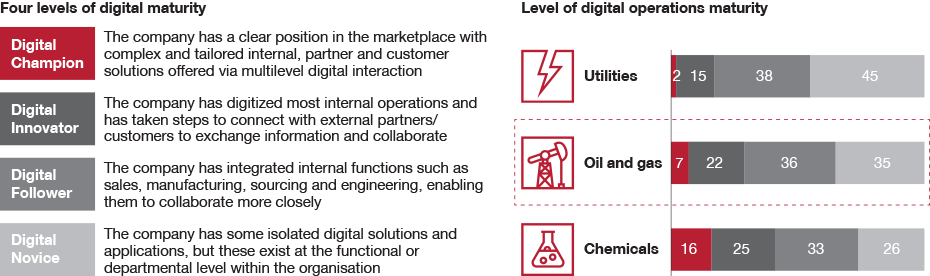

The challenge? The Oil & Gas industry has farther to go than other sectors in its digital readiness journey. Just 7% of Oil & Gas companies considered themselves to be Digital Champions, according to PWC's 2020 digital operations study.

The first step in this journey is selecting the right initiatives to focus on. For organizations that are Digital Novices, it is crucial for them to carefully consider whether they possess the necessary in-house expertise to successfully execute their desired projects. It is important to note that implementing the technology is only half of the equation; organizations must also be prepared to educate and empower their workforce.

How is Digital Transformation Occuring?

Digitization is not uniform throughout the oil and gas sector. Companies need to determine which technological advancements make the most sense for them to pursue as well as calculate return on investment to determine which initiatives should be prioritized first.

Below are eight examples of ways oil and gas companies are embracing digitization:

|

|

|

|

1. Driving Data Utilization for Decision Making The energy industry is seeing vast amounts of data generated from sensors, equipment, and operations. Ensuring that this data is properly tracked, managed, and stored allows companies to derive valuable insights that can help improve decision making. Data transformation is often required before other digital transformation efforts can begin. |

2. Automating Hazardous Tasks & Improving Safety Drones and robotic equipment can be programmed to do maintenance tasks and inspections in dangerous environments, reducing human risk and exposure. Advanced analytics and machine learning can process large quantities of data, picking up on abnormal patterns and identifying potential safety concerns in operations, avoiding major incidents. |

|

|

|

3. Optimizing Drilling Output Drilling remains one of the largest expenses in oil and gas production. Deploying advanced analytics can help operators increase their drilling speeds by 25% and cit idle drilling time in half, according to McKinsey. |

4. Remote Monitoring Hard-to-Reach Sites Digitization allows companies to manage assets, detect anomalies, and respond to issues without needing needing physical on-site presence. This has the potential to result in significant cost reductions within the oil and gas industry, as numerous sites are situated offshore and in remote areas. |

|

|

|

5. Ensuring Environmental & Regulatory Compliance There is increasing pressure for oil & gas companies to reduce carbon emissions and abide to stricter environmental standards. Environmental Monitoring systems (EMS) can ensure accurate tracking and reporting of emmissions data. Data transformation & real-time analytics can ensure optimal resource usage, lowering production waste and emissions. |

6. Harnessing the Power of Predictive Maintenance Did you know that the average oil & gas company has 27 days of unplanned downtime per year at a cost of $38 million dollars? Organizations see an average reduction in equipment downtime of 36% when they leverage historical and real-time data for predictive modeling. This means they can identify and fix potential problems before equipment malfunctions.

|

|

|

|

7. Increasing Employee Productivity with Augmented Reality There are many applications for Augmented (AR) and Virtual (VR) reality in Oil & Gas. Instead of having to conduct training at remote job sites, employees can receive simulated virtual training. This ensures ample practice before touching expensive and complex machinery. |

8. Optimizing Logistics with IoT Data and Artificial Intelligence Transportation of resources remains a significant cost in the oil & gas sector. By leveraging IoT sensor data and utilizing AI to process large quantities of data, companies can optimize delivering their products to market. This can reduce vehicle costs by up to 20%. |

How can Companies Ensure Success?

Digital transformation is in the early stages of revolutionizing how the oil and gas industry operates. With volatility in oil prices, growing environmental concerns, and rising production costs, companies that are quickest to embrace these changes will gain a competitive advantage over peers who lag behind.

To ensure digital transformation is successful, companies must think holistically. This first requires evaluating business goals and challenges to determine what technology investments make sense. It's critical to avoid siloed decision making, where every division of the organization chooses different tools. Companies must ensure their departments are collaborating on their approach. Finally, companies must evaluate whether their workforce is ready for change. This may require cultural changes, training investments, or bringing new skillsets into the organization.